Bridgeport Milling Machine Manual⁚ A Comprehensive Guide

This comprehensive guide delves into the world of Bridgeport milling machines‚ providing valuable information for both beginners and experienced machinists. From the history and evolution of these iconic machines to their operation‚ maintenance‚ and applications‚ this manual serves as a one-stop resource for all things Bridgeport.

Introduction to Bridgeport Milling Machines

The Bridgeport milling machine‚ a staple in machine shops worldwide‚ is a versatile and robust tool renowned for its precision and ease of use. These machines‚ commonly known as “Bridgeports‚” are vertical spindle‚ knee-mill machines with a swiveling head‚ allowing for a wide range of milling operations. Their compact design and intuitive controls make them ideal for both hobbyists and professionals alike. While Bridgeport machines are known for their manual operation‚ they are also available in CNC versions‚ offering advanced automation capabilities.

The heart of the Bridgeport milling machine is its robust cast iron construction. This design ensures stability and rigidity‚ crucial for precise machining. The machine’s knee‚ which supports the table‚ allows for vertical adjustment‚ while the table itself can be moved horizontally and longitudinally. These movements‚ combined with the swiveling head‚ provide a wide range of machining possibilities. The spindle‚ powered by a motor‚ rotates a cutting tool‚ removing material from the workpiece to achieve the desired shape and dimensions.

History and Evolution of Bridgeport Mills

The Bridgeport milling machine’s story began in 1938 when the Bridgeport Machines‚ Inc. company‚ located in Bridgeport‚ Connecticut‚ introduced its first model. This innovative design quickly gained popularity due to its compact size‚ ease of use‚ and impressive precision. Over the years‚ Bridgeport continued to refine its milling machines‚ introducing various improvements and enhancements. The most notable of these was the development of the “J-head” model‚ featuring a variable-speed spindle‚ which significantly expanded the machine’s capabilities.

The original Bridgeport milling machine was a manual machine‚ requiring the operator to control all movements. However‚ as technology advanced‚ Bridgeport embraced CNC technology‚ incorporating computer numerical control into its machines. This advancement allowed for automated operation‚ increasing efficiency and precision. The introduction of CNC capabilities broadened the applications of Bridgeport milling machines‚ making them suitable for more complex and demanding tasks.

Today‚ the Bridgeport name remains synonymous with quality and reliability in the machine tool industry. While the original company no longer exists‚ the legacy of the Bridgeport milling machine lives on through various manufacturers who produce machines based on the original design principles. The Bridgeport continues to be a popular choice for workshops and factories worldwide‚ a testament to its enduring design and versatility.

Series I Bridgeport Milling Machines

The Bridgeport Series I milling machine‚ a cornerstone of the brand’s legacy‚ is renowned for its robust construction and enduring performance. This series‚ characterized by its compact size and versatility‚ is highly adaptable for a wide range of machining tasks. Series I machines are often found in workshops and factories‚ proving their enduring value for both hobbyists and professionals. The inherent versatility of the Series I is further enhanced by its ability to accommodate various accessories‚ expanding its machining capabilities. This adaptability makes the Series I a valuable asset for a diverse range of applications.

The Series I Bridgeport milling machine is a testament to the brand’s commitment to quality and reliability. These machines are known for their precision‚ durability‚ and ease of use‚ making them a preferred choice for both experienced and novice machinists. Whether performing basic milling operations or tackling more complex tasks‚ the Series I proves its worth as a dependable and versatile machine. Its enduring popularity is a testament to its enduring design and the dedication of its creators to producing high-quality machine tools.

A key characteristic of the Series I Bridgeport milling machine is its variable-speed spindle. This feature allows for precise control over the cutting speed‚ which is crucial for achieving optimal machining results. The Series I also features a robust construction‚ ensuring stability and accuracy during operation. Its compact design makes it ideal for workshops and factories with limited space. The combination of these features has contributed to the Series I’s enduring popularity and its status as a classic in the world of machine tools.

3.1. Features and Specifications

Series I Bridgeport milling machines are known for their distinctive features‚ which contribute to their versatility and enduring performance. One of the key features is the variable-speed spindle‚ allowing for precise control over the cutting speed‚ crucial for achieving optimal machining results. The Series I also boasts a robust construction‚ ensuring stability and accuracy during operation. The compact design makes it ideal for workshops and factories with limited space. This combination of features has earned the Series I its reputation for reliability and versatility.

The Series I Bridgeport milling machine is equipped with a range of specifications that cater to diverse machining needs. It features a 1.5-horsepower motor‚ providing sufficient power for various milling operations. The machine’s table‚ measuring 16″ x 30″‚ offers ample workspace for various workpieces. The Series I Bridgeport also features a 12″ vertical travel and a 10″ longitudinal travel‚ allowing for precise movements and adjustments during machining. These specifications‚ coupled with the machine’s robust construction and versatile features‚ make it a valuable asset in a variety of machining environments.

The Series I Bridgeport milling machine is designed for precision and durability‚ with features that ensure accuracy and ease of use. The machine’s hand-scraped ways provide smooth and precise movement‚ minimizing vibration and ensuring accurate machining results. The Series I also features a quill feed handle‚ which allows for precise control over the depth of cut. These features‚ coupled with the machine’s robust construction and versatile specifications‚ contribute to its enduring popularity and its status as a classic in the world of machine tools.

3.2. Operation and Maintenance

Operating a Series I Bridgeport milling machine requires a clear understanding of its controls and functions. The machine features a range of controls‚ including the spindle speed control‚ feed rate control‚ and table movement controls. Before operating the machine‚ it’s essential to familiarize yourself with each control and its function. A thorough understanding of the machine’s controls ensures safe and efficient operation.

Proper maintenance is crucial for extending the lifespan and ensuring the optimal performance of a Series I Bridgeport milling machine. Regular lubrication of the machine’s moving parts‚ such as the ways‚ gears‚ and bearings‚ is essential. Cleaning the machine after each use is also crucial for preventing the buildup of debris and ensuring the machine’s smooth operation. Following the manufacturer’s recommended maintenance schedule ensures that the machine remains in top working condition.

The Series I Bridgeport milling machine is designed for long-term reliability. However‚ like any machinery‚ it requires proper care and maintenance to perform at its best. Regular inspections for wear and tear‚ prompt replacement of worn-out parts‚ and adherence to the manufacturer’s guidelines contribute to the machine’s longevity. Proper operation and maintenance ensure that the Series I Bridgeport remains a reliable and productive asset in your workshop or factory.

3.3. Parts List and Troubleshooting

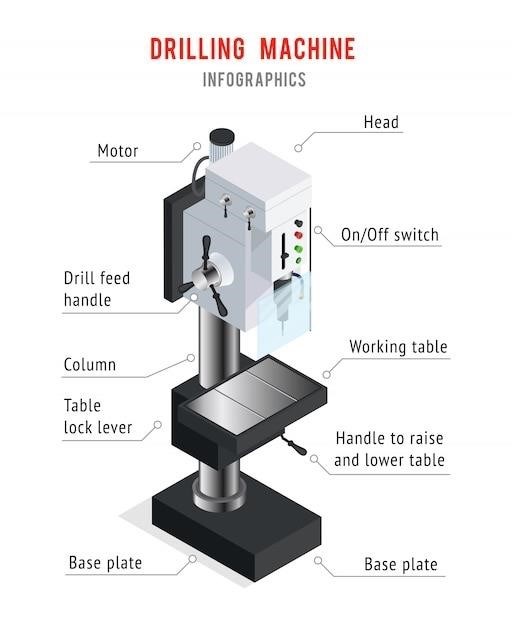

The Series I Bridgeport milling machine manual includes a comprehensive parts list‚ making it easy to identify and order replacement components when needed. This list details all the essential parts of the machine‚ including the head‚ table‚ knee‚ column‚ and base. Each part is assigned a unique part number‚ simplifying the ordering process. The manual also provides detailed diagrams and descriptions of each part‚ ensuring accurate identification.

Troubleshooting is an inevitable part of working with machinery. The Series I Bridgeport manual includes a section dedicated to troubleshooting common issues. It covers a wide range of problems‚ from spindle speed issues to table movement problems. For each problem‚ the manual provides possible causes and recommended solutions. This section serves as a valuable resource for quickly diagnosing and resolving common issues.

The manual also provides guidance on accessing additional resources for troubleshooting. It lists authorized repair centers‚ online forums‚ and other sources of information. This comprehensive approach empowers users to effectively diagnose and resolve problems‚ ensuring the continued smooth operation of their Series I Bridgeport milling machine. A well-maintained and properly troubleshooted machine ensures optimal performance and productivity.

Series II Bridgeport Milling Machines

The Series II Bridgeport milling machine‚ introduced in the 1980s‚ represents a significant evolution from its predecessor. It boasts a more robust design‚ increased power‚ and enhanced features. The Series II is characterized by a heavier cast iron construction‚ resulting in improved stability and rigidity for handling larger and heavier workpieces. This increased weight and robust design contribute to its reputation for precision and durability.

A notable feature of the Series II is its four-horsepower head‚ a significant upgrade from the Series I. This powerful head allows for deeper cuts and higher feed rates‚ enabling the machine to handle more demanding machining operations. The Series II also incorporates improvements in the table design‚ including a larger table surface area and a wider range of table movement capabilities. These enhancements provide greater versatility and accommodate larger workpieces;

The Series II Bridgeport milling machine is designed for a wide range of applications‚ including general milling‚ contouring‚ thread milling‚ and boring. Its improved power‚ stability‚ and precision make it a reliable and versatile choice for various industries‚ including automotive‚ aerospace‚ and manufacturing. The Series II manual provides detailed information on operating‚ maintaining‚ and troubleshooting this advanced milling machine.

Bridgeport Milling Machine Applications

Bridgeport milling machines are renowned for their versatility and ability to handle a wide range of machining operations. Their adaptability stems from their robust construction‚ precision‚ and power‚ making them suitable for various industries and applications. From basic milling operations to more complex tasks like contouring‚ thread milling‚ and boring‚ Bridgeport machines are capable of meeting diverse machining needs.

One of the most common applications for Bridgeport milling machines is general milling. This involves removing material from a workpiece to create specific shapes or features. Bridgeport machines excel in this area due to their accuracy‚ stability‚ and ability to handle various cutting tools. Another frequent application is contouring‚ where the machine precisely follows a predetermined path to create intricate shapes or designs. Bridgeport mills are particularly well-suited for this task due to their smooth and controlled movement.

Bridgeport milling machines are also often used for thread milling‚ a process that involves cutting threads into a workpiece. The machines’ precision and ability to handle fine movements make them ideal for this application. Additionally‚ Bridgeport machines are employed for boring‚ which involves enlarging existing holes to a precise diameter. This versatility and adaptability make Bridgeport milling machines valuable assets across numerous industries‚ from automotive and aerospace to manufacturing and engineering.

Safety Precautions and Best Practices

Operating a Bridgeport milling machine requires a commitment to safety and adherence to best practices to ensure a safe and productive working environment. Before operating the machine‚ it is crucial to familiarize yourself with all safety features‚ controls‚ and procedures. Always wear appropriate personal protective equipment‚ including safety glasses‚ hearing protection‚ and work gloves. Never operate the machine with loose clothing or jewelry that could become entangled. Keep your work area clean and free of clutter to prevent accidents. Ensure proper lighting to enhance visibility and reduce the risk of eye strain. Never attempt to operate the machine if you are tired or under the influence of drugs or alcohol.

Always follow the manufacturer’s instructions and warnings outlined in the manual. Before starting any operation‚ inspect the machine for any signs of damage or wear. Check the cutting tools for sharpness and ensure they are securely mounted. Use appropriate cutting fluids for lubrication and cooling. Always use the proper speed and feed rate for the material and cutting tool being used. Never reach into the machine’s cutting area while it is in operation. Use the machine’s safety guards and enclosures as intended. If you encounter any problems or malfunctions‚ stop the machine immediately and seek assistance from a qualified technician.

By following these safety precautions and best practices‚ you can significantly reduce the risk of accidents and ensure a safe and productive working environment when operating a Bridgeport milling machine.